Ponad 100 lat poświęconych postępowi technicznemu - tak najprościej można opisać naszą działalność w zakresie technologii robotycznej i automatyki Yaskawa.

Montaż

Opis produktu

Assembly and Disassembly with Motoman Robots

Industrial robots can be used to automate the tasks involved with putting together or disassembling a product, such as industrial or automotive components and machinery, furniture, or electronics components. Robots can either manipulate an assembly tool (e.g. nutrunner), or move the workpiece to/from a stationary assembly station. In this case, specialized gripper tooling is attached to the end of the arm, to manipulate parts and assemblies in several stages.

What is Robotic Assembly ?

Assembly (and Disassembly) is a coordinated sequence and combination of many individual operations, like part identification, part sortation, part separation, part feeding, part handling, part positioning, gripping, inserting, fastening/joining, quality inspection and auxiliary up- and downstream operations like cleaning, deburring, unpacking, sealing, engraving, labelling .... and hundreds more! The robot controller is in the middle of a communication flow, receiving data (part ID, job ID) or sending data to control tools, submitting status data to Line PLCs, MES systems or the cloud. This makes robotic assembly jobs challenging - and really interesting!

Design for Assembly

Based on the classic automation philosophy, it is always desirable to offer the parts to the robot as well sorted and positioned as possible, on a workpiece carrier, in a grid, a rack, on a tray or on a geometric layer. Fixtures are used both to present the parts to be assembled and to hold/fasten/clamp the parts in position during the multi-step assembly process.

Flexible Robotic Assembly

Maar de tijden zijn veranderd, en flexibiliteit is een van de robotgenen - gunstig voor de groeiende eisen van de hedendaagse flexibele automatisering. Tegenwoordig kunnen robots "zien" en "voelen", en geavanceerde logica verwerken en communiceren. Geavanceerde technologieën zoals machine vision, kracht-/torsiedetectie en communicatiemogelijkheden op apparaat-/cel-/lijn-/fabrieks- en cloudniveau zijn beschikbaar, waardoor robotassemblage veel flexibeler en veelzijdiger is in termen van werkstuk-/job-/werkstroomvariaties, in vergelijking met gekoppelde, aaneengeschakelde productiemachines.

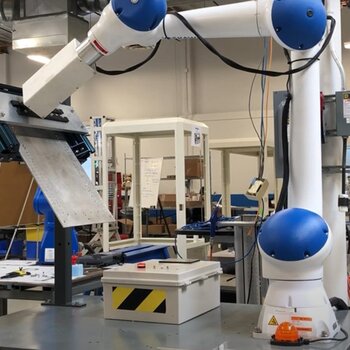

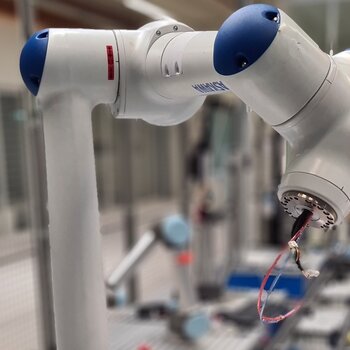

Motoman Robot Models suited for Assembly/Disassembly

Motoman 6/7-Axis Handling Robots

Gewoonlijk bevelen wij het kleinere assortiment van onze Handling Robots aan, met name onze GP-serie 6-assige robots voor assemblagewerkzaamheden, samen met onze YRC1000 of YRC1000micro controllers. Ze zijn veelzijdig, bieden een hoge snelheid, een hoge positioneringsnauwkeurigheid en alle media-aanvoer- en connectiviteitsopties die u nodig hebt.

De bewegingsmogelijkheden van onze SIA-serie 7-assige robots zijn nog geavanceerder voor smalle ruimtes.

.

Assembly with Motoman Collaborative Robots (HC Series)

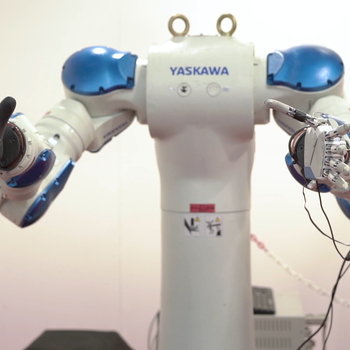

Motoman Dual Arm Robots for Assembly/Disassembly (SDA Series)

Using a dual arm robot to automate assembly tasks is pretty straight forward - let the robot copy the scope of a manual worker. However, a successful installation of an SDA Dual Arm robot often starts with an inspired application idea, doing things different, being innovative, radical or disruptive – what is your idea?

2D/3D Machine Vision in Robotic Assembly / Disassembly

In Assembly, Machine Vision takes over many roles - some examples are:

- detecting the presence of a part

- detecting the status of a fixture (empty, part clamped)

- detecting location of parts on a table, a tray or a conveyor, even when not being well aligned.

- inspection of part features to identify variants

- inspection of all kind of assembly results (completeness, fill level)

Machine Vision cameras can be mounted either statically (on a gallow over the object) on the robot arm itself - the robot controls the machine vision system in both cases.

Over the last years, Machine vision has become very fast, reliable, easy-to-use and attractive in terms of cost, training and integration efforts are not show stoppers any more. They could be a more flexible and efficient alternative to a population of classical proximity sensor installations.

YASKAWA Motoman are offering our own, fully integrated Smart Camera System MotoSight2D, which is absolutely easy-to-use and perfect to tell the robot where to pick a part. Some 3rd party Plug&Play Vision Suppliers, registered in our Smart Series Program, offer a Plug-and-play solution in combination with our robots.

But when it comes to more advanced or sophisticated vision applications, we rely on our network of professional Machine Vision experts. As a robot supplier, we just make sure that those vision systems can be seamlessly integrated with our robot systems, providing easy integration interfaces like VSTART. Our Motoplus C++ SDK Software Development Kit provides comfortable APIs for effective and fast software driver development. But in many cases we do not need to start from scratch. Many system integrators and machine vision suppliers in our worldwide partner network have excellent integration experience with Motoman Robots, and we ourselves can fall back to our rich repository of interface and software driver solutions to ensure that it works.

But when it comes to more advanced or sophisticated vision applications, we rely on our network of professional Machine Vision experts. As a robot supplier, we just make sure that those vision systems can be seamlessly integrated with our robot systems, providing easy integration interfaces like VSTART.

Our Motoplus C++ SDK Software Development Kit provides comfortable APIs for effective and fast software driver development, including the wide ROS community. But in many cases we do not need to start from scratch. Many system integrators and machine vision suppliers in our worldwide partner network have excellent integration experience with Motoman Robots, and we ourselves can fall back to our rich repository of interface and software driver solutions to ensure that it works.

Sensitive Assembly using the Servofloat Option

YASKAWA Servofloat is a great option to switch robot motion axes to soft mode for supporting joining motions with tight tolerances. This allows sensitive joining motions where the fit tolerances are relatively tight, or where the target position cannot be taught precisely, without jamming the workpieces. With the Servofloat option, external forces (resulting from lead-in chamfers) move the manipulator since the torque control has priority over the position control.

The sensitive motion may include configurable single axes ("link servofloat") or combinations of robot axes ("linear servofloat"), so that the assembly direction motion can be either defined in a circular or linear as a Cartesian vector based on the robot coordinate system.

Sensitive Robotic Assembly with Force/Torque Sensors - Motofit

When common robot software functions like Force Limitation or Servofloat get to their limits (in terms of process sensitivity, part damage avoidance or safety) force sensing is often needed for insertion or tightening operations. A force sensor provides feedback to the robot control system and can measure forces and torques being applied at the end-effector. The YASKAWA MotoFit force control assembly tool alters the robot’s position based on the force encountered to align or assemble parts.

If you prefer your own force/torque sensor brand, the YRC1000/FS100 Controllers provide excellent Standard Sensor communication interfaces, e.g. fast digital and analogue inputs, integrated Ethernet and other fieldbus interfaces. In case that standard options are not available, all kind of sensor drivers can be developed and deployed using the Motoplus C++ SDK environment.

Sensitive Assembly Operations with Force Feedback can be trained by neural networks.

Robot Grippers and Tool Changers

Our Gripper Network

In Assembly, same as in Handling, Pick & Place applications, the gripper design is crucial for the success of the application. Gripper design is a wide field requiring deep expertise. Again here, YASKAWA cooperate and support a broad network of gripper and accessory suppliers. We benefit from their know-how and design our hardware and software interfaces in a way to ensure perfect functionality with our robots.

Along with our gripper technology network partners, for example in our Smart Series Initiative, we offer Plug and Play solutions perfectly tailored to our robot models.

Flexible Robot Gripper Solutions

Robotic Assembly jobs are often very versatile, requiring the gripping of many different parts or assemblies in different assembly stages. Grippers can be designed to cover this flexibility, either by adding complexity (multi-finger grippers) or reducing complexity (2-finger grippers), turning the robot's wrist, or using multi-position grippers. For adaptable grippers with integrated motion, consider to operate the motion directly by the robot controller as external servo axes.

Automatic Gripper Tool Changers

When the gripper design compexity reaches it's limits, tool changers always work. YASKAWA robot controllers support quick automatic docking procedures with fast recovery of electric/fieldbus/pneumatic signal exchange, and are able to manage a large library of different tools.

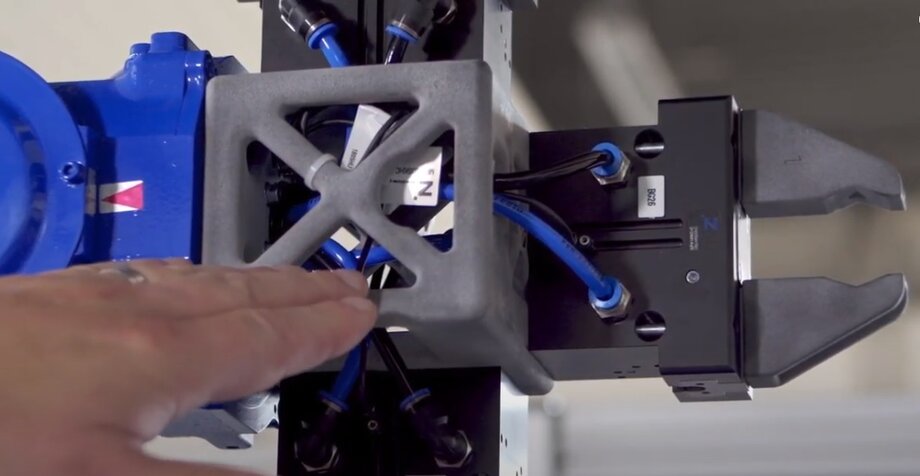

3D Printed Grippers and Gripper Parts for Motoman Robots

By the way, the 3D printing technology is used for robotic grippers and their spare parts (gripper fingers). 3D Printing Technology allows fast compact and lightweight gripper design by integrating all functions, e.g. pneumatic supply, into the gripper housing. Gripper fingers are printed out in minutes. 3D printing is used for gripper prototyping, iterating to the perfect gripper finger design for an application.