Ponad 100 lat poświęconych postępowi technicznemu - tak najprościej można opisać naszą działalność w zakresie technologii robotycznej i automatyki Yaskawa.

Robotics at the service of craftsmanship

Located in the heart of the Langhe, Mulino Marino is one of the pearls of excellence in the Piedmontese agri-food scene., ever since Since 1956 The Marino family has dedicated itself with great passion to developing this activity, moving more and more towards organic, until, in 2001, it totally abandoned the production of conventional flours to produce only and exclusively certified 100% organic flours both natural stone and cylindrical.

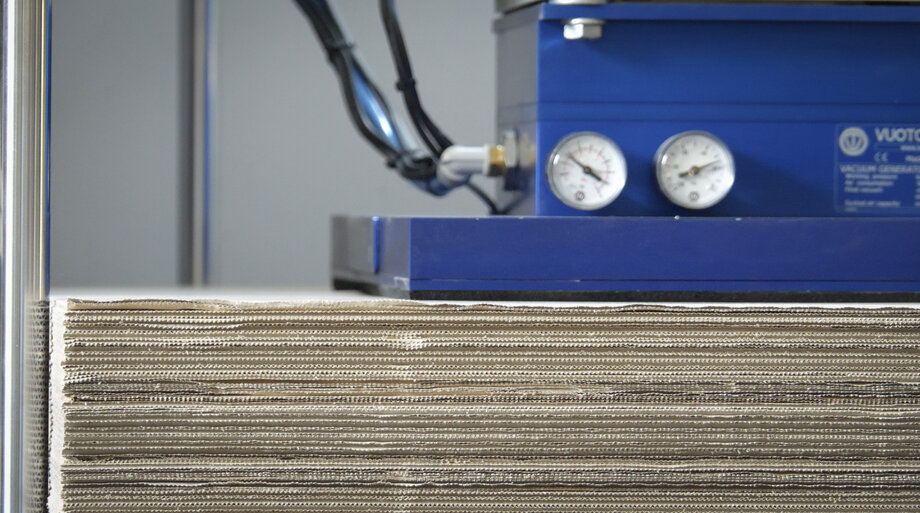

Since 1965 there have been a series of modernization interventions, always careful to respect tradition and concentrated mainly in the part ancillary to milling. Today Mulino Marino has 10 natural stone mills with which it produces natural stone ground organic flours, in a perfect synthesis of tradition and innovation.

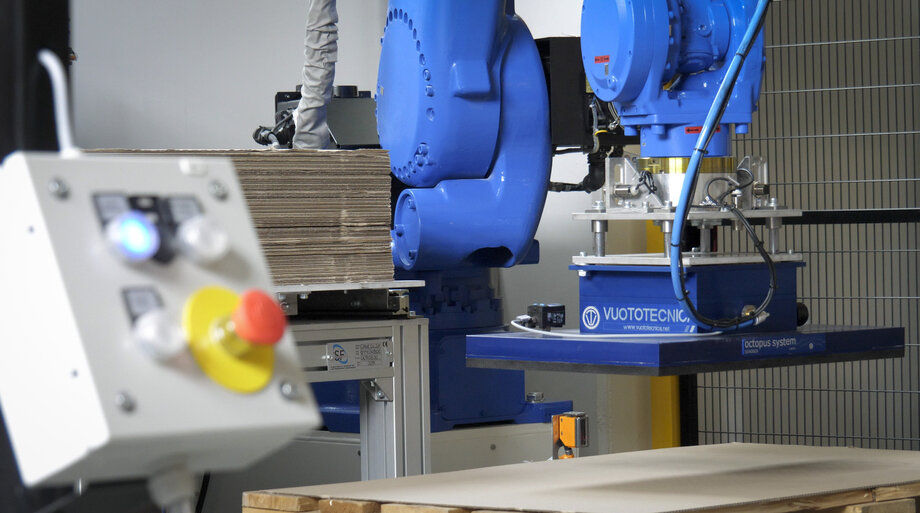

To modernize and make the flour sack palletizing business more effective, the company decided to equip itself with a new system capable of handling the company's high production. With the support of SF Automazioni, an integrator that Mulino Marino had already chosen some time ago as a solution was devised to automate the palletizing activity through the use of a robot arm intended to serve 7 of the 10 mills in use.

At the heart of the application is a Motoman MPL 100 robot from Yaskawa, which takes care of the activity in its entirety: it picks up pallets from a special warehouse, then provides for the insertion of an interpallet cardboard sheet and the stacking of the bags, which are previously packed by two bagging machines and transferred to the loading station via a roller system.

The challenge

The robot faces the challenge of handling different types of objects - pallets, interpallet sheet, and flour sacks - with the same vacuum gripper. In addition, both multiple bag sizes - 10 -25 or 50 kg - and multiple stacking layouts are handled. In fact, depending on the end customer's needs, pallets can be composed with different geometries, which can be set from the operator panel.

"We needed a robot that was not only versatile enough to allow this flexibility, but also had enough reach to reach all of the individual element pick stations. This may seem like an obvious point, but in this application it proved to be a really sensitive one, particularly when processing small bags. The problem was solved by equipping the robot arm with a special extension," comments Eugenio Fissore, Administrator of SF Automazioni.

The solution

Once the sack is picked up, the robot performs a particular series of movements specifically designed to increase pallet stability, from the initial pressure intended for leveling to the positioning managed with a diagonal approach. An additional interpallet carton is placed every 4 or 5 layers, further safeguarding the quality and stability of the packaging. The completed pallet is then conveyed to the next stages by an additional roller system.

The benefits

The high pace of production required handling a significant robot cycle. Motoman MPL 100 proved to be fully up to the task, so much so that the customer is considering installing another one to replace the other existing palletizing line, based on a 4-axis gantry solution, to make it more performant.

Moreover, since traceability is a key issue for the food industry, the palletizing station is also connected to the office system to exchange due product data.