Ponad 100 lat poświęconych postępowi technicznemu - tak najprościej można opisać naszą działalność w zakresie technologii robotycznej i automatyki Yaskawa.

Obróbka i opakowania z drewna

Yaskawa Polska Aplikacje Branże Obróbka i opakowania z drewna

Overview

Maximum performance for every process

No matter how large a woodworking machine is designed, everything is about the quality and throughput of the final product. With Best in Class Components and an open and connectable architecture, Yaskawa provides an important contribution to performance. And has done so for decades.

Energy-efficient AC drives for spindle motors, transport and ventilation systems

Wether put in a control cabinet or at a wall, in a clean or harsh environment, the flexible package design of the GA700 allows a reliable operation under various environmental conditions.

Limitless possibilities

With flexible motor control, powerful and extendable functionality, and a broad power range up to 630 kW, the GA700 is the drive of choice for almost any task, ranging from simple transportation, presses and others up to complex systems with network-connected drives or the demand for higher levels of safety.

Yaskawa opens up new possibilities of energy efficiency and energy saving for fans and other applications with variable torque, using the latest inverter drive technology.

Servo drive technology for high-precision work

With more than 12 million servo systems in the field, Yaskawa has lots of experience and technical know-how in motion and control. The result: Excellent performance and an extremely low fault rate. Startup is possible in just a few minutes. With the new Sigma-7 series, you achieve an unprecedented level of precision.

Sigma-7 Servo systems for CNC machines

The development of the new Sigma-7 series focused on three main goals: consistently fast commissioning, high production output and maximum operational reliability. The prerequisites for this are provided by intelligent functions such as autotuning, automatic load adjustment or integrated vibration suppression. New book-style housing supports gapless side-by-side installation of amplifiers even in small spaces for high-performance density inside a cabinet.

The series offers a powerful response to today‘s market requirements for both machine constructors and final customers in the production industry.

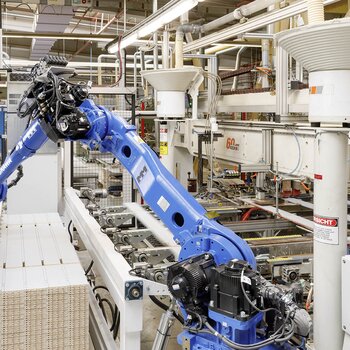

Robots for handling, packaging and more

Robots offer many advantages due to their speed, precision and cost-effectiveness. They also ensure a consistent quality standard and high repeatability. They guarantee a high return on investment and are suitable for handling, sawing, grinding, polishing, milling or quality control, 24 hours a day, all year round.

MOTOMAN MH series

The MOTOMAN MH series offers flexible 6-axis high-speed robots for a variety of applications such as handling, machine loading, processing and distribution applications. The MH models have a load capacity of up to 600 kg and a working range of 532 mm to 3,106 mm. The compact design allows for close positioning on the workpiece and reduces cycle times.

18 Motoman robots make it possible for IKEA to produce an assembled, flat-packed "Billy" bookcase kit every 6 seconds! That is 40,000 units per week.

The robotic solution also helps save 20% in production costs. This video illustrates various handling and palletizing applications.

Operating and monitoring with HMI and PLC

The interaction between man and machine is usually carried out via control units, which are connected to the control of the systems. From the smallest system up to a large, multi-networked machine: Yaskawa offers the entire spectrum of HMI and PLC for a variety of applications.

Touch Panels & Panel PCs

With the Panel PC series, you are optimally equipped for all control and monitoring tasks. The combination of Industrial PCs with state-of-the-art performance features and Touch Panels with optimum display options concentrates high performance in a small space.

VIPA MICRO M13C

With VIPA MICRO, Yaskawa presents a very compact and extremely fast micro control system. The design has a definite wow-factor and opens up completely new paths as regards operating and status display. Thus the VIPA MICRO M13c is the starting signal for the new controller generation from Yaskawa.

VIPA SLIO I/O

SLIO is an extremely compact I/O system with fast backplane bus, single-channel diagnostics LEDs and standing wiring. It offers the highest cost-effectiveness through its modular concept, especially in assembly and service. The combination with systems from other CPU manufacturers is easy and possible without restrictions. It is one of the most efficient and advanced decentral I/O systems available on the market. SLIO combines the highest functionality with a clever mechanical concept in an extremely compact and maintenance-friendly design.

Processing and Packaging of Wooden Products

Motoman Robots give you full freedom to realize complex 3D shaped wooden design objects. The robot controller is connected to a CAD/CAM Milling Software which translated CAD Information into a Milling Trajectory. Sawing typically, the robot is moving the workpiece under a stationary saw. Due to their high path precision and vibration stability, Motoman Robots can perform trajectories with perfect rounds and complex shapes - e.g. for Wooden instruments or ornaments.

The use of Motoman Robots in Furniture is described in a separate chapter.

Handling Wooden Panels with Motoman Robots

A very typical robotic application is handling Wooden Panels in and out of a sawing table, allowing cutting of individual geometries on one machine.

Milling Wooden Material with Motoman Robots

Motoman Robots give you full freedom to realize complex 3D shaped wooden design objects. The robot controller is connected to a CAD/CAM Milling Software which translated CAD Information into a Milling Trajectory.

Drilling Wooden Material with Motoman Robots

Sawing Wooden Material with Motoman Robots

Typically, the robot is moving the workpiece under a stationary saw. Due to their high path precision and vibration stability, Motoman Robots can perform trajectories with perfect rounds and complex shapes.

Glueing Wooden Workpieces with Motoman Robots

Glueing of wooden workpieces is a great and easy application for Motoman Robots.

Wooden Pallet Assembly and Repair with Motoman Robots

Automated Robotic Pallet Repair has been invented and pioneered by YASKAWA. For more details, information about Pallet Dismantling, Repair and Assembly, please check our "Pallet Repair" Application Section.

Wooden Furniture Assembly with Motoman Robots

for more details, please refer to our separate "Furniture" section.

Palletizing Wooden Pellet Bags with Motoman Robots

For more generic information about Palletizing applications, please refer to the "Palletizing" section of our web page.